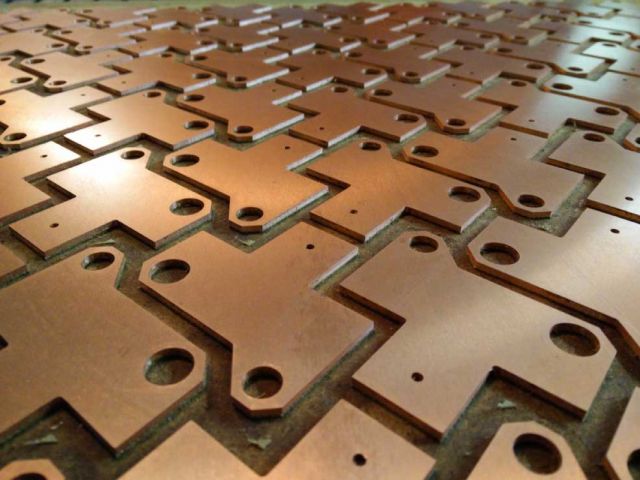

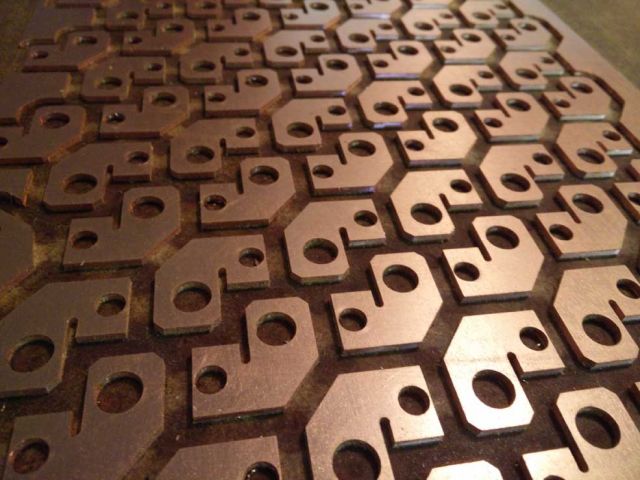

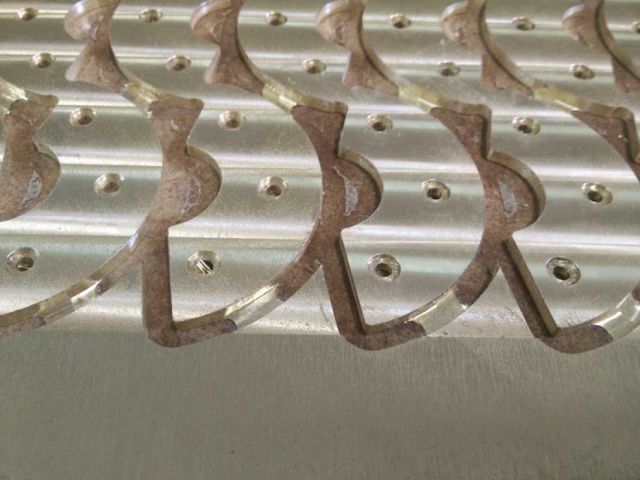

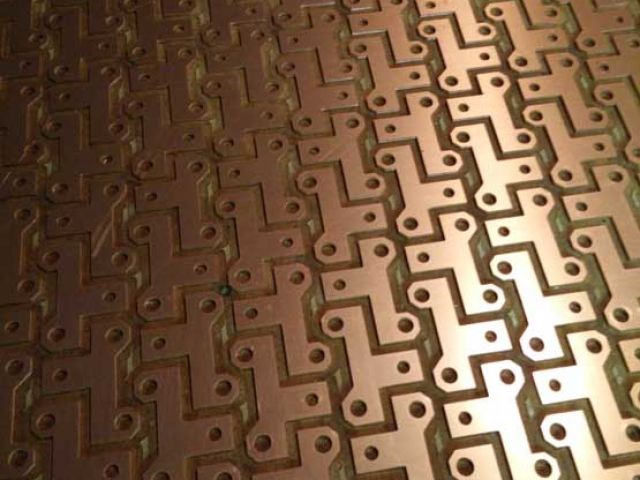

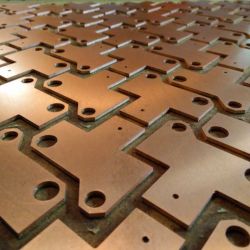

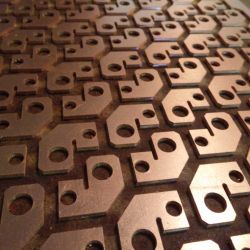

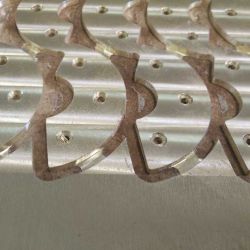

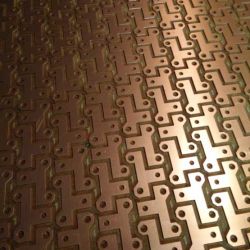

CNC cutting of non-ferrous metals is carried out on a portal milling machine with an accompanying vacuum table, which enables the processing of both smaller and larger format pieces, whereby the maximum format of the workpiece can be 1250 mm x 2500 mm. It is possible to mill both the sheets as well as the plates. The machine’s accuracy is +/- 0.05 mm. As mentioned above, the non-ferrous metals (aluminium, copper, and brass) are cut and milled on a vacuum table. Oil mist (MQL Technology) and frozen air are used in order to cool the metal components. Such processing provides, especially, an alternative to waterjet and laser cutting, as it allows a high-precision, straight, burr-free edges without the needle, and also the processing of plates. One of the advantages certainly also presents the processing without the necessary reattachment, as, namely, the product can both be cut out and different shapes can be milled in one single phase.

Materials:

- Aluminium,

- Copper,

- Brass,

- Alucobond

- …

Advantages:

- Processing of very small pieces,

- Processing of larger formats up to 1250 mm x 2500 mm,

- Accuracy within +/- 0.05 mm,

- Straight, burr-free edges,

- Several operations in a single phase,

- Processing of both thinner and thicker plates,

- Quality and low-cost,

- No deformations due to temperature,

- Processing without the use of cooling and lubrication emulsion.