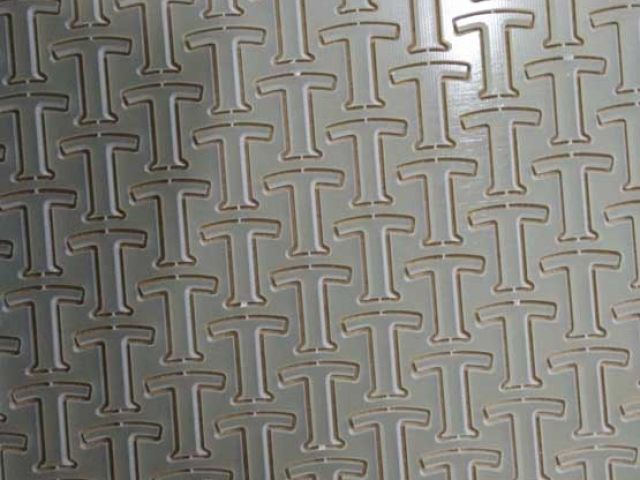

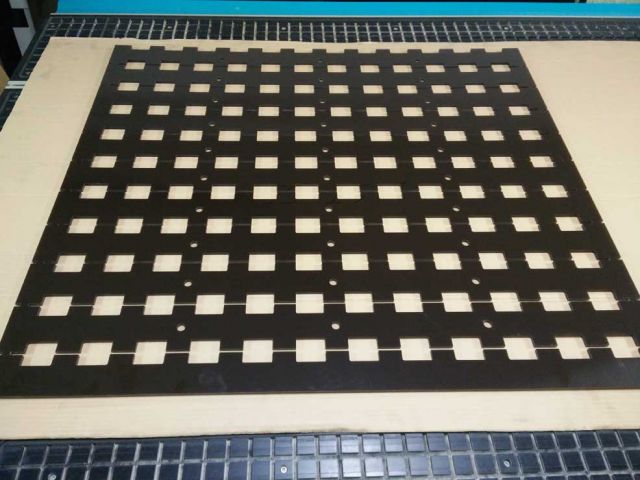

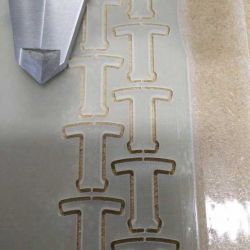

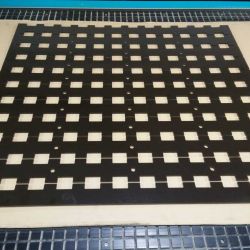

CNC cutting of electroinsulating materials is carried out on a portal milling CNC machine. A workpiece is hold down by means of a vacuum table, which allows us to cut and mill various shapes from all sides in a single phase. The milling is done by special milling cutters, whilst using frozen air. We are able to process both smaller, as well as larger formats of up to 1250 mm x 2500 mm. The machine’s accuracy is +/- 0.05 mm. Thanks to dust extraction system, we are also able to cut materials containing fiberglass, carbon fibres, phenolic resin, epoxide resin, dust, etc. It is necessary to emphasise the fact that there is no stratification of materials in the case of composite plates (fiberglass epoxy laminated sheet, pertinax/phenolic sheet, melamine sheet, alucobond), as can otherwise be seen in the case of waterjet cutting or punching, but their edges come out straight, smooth and non-stratified.

Materials:

- Fiberglass epoxy laminated sheet (FR-4, G-10, G-11),

- Pertinax/phenolic sheet,

- Textolit sheet,

- Alucobond,

- Carbon fiber sheet,

- Acrylic (plexiglass) glass,

- HPL plates (compact plates),

- Melocart (melamine sheet),

- Plastics, etc.

- Insulation boards for die casting moulds (meusburger E 1405, E 1425, E 1450, ...)

- …

Advantages:

- Straight, smooth, and non-stratified edges,

- Processing of very small pieces,

- Processing of larger formats up to 1250 mm x 2500 mm,

- Accuracy within +/- 0.05 mm,

- Several operations in a single phase,

- Processing of both thinner and thicker plates,

- Quality and low-cost,

- Processing without emulsion – pieces are clean and non-greasy.